Loading...

Loading...

There is often a significant disconnect between ideal digital workflows and the reality of the job site. While the industry aims for fully integrated BIM (Building Information Modeling) lifecycles, the day-to-day reality for most estimators, General Contractors (GCs), and planners relies on static documentation: PDFs, scanned tender documents, and 2D drawings.

This reliance creates a "Data Gap." Valuable information remains locked inside lines and symbols, requiring manual interpretation. Furthermore, because contractual evaluations and liability checks often rely on document-based reviews rather than model-based verification, traditional 2D documentation remains a necessary standard.

Even as BIM adoption grows, extracting data from 2D blueprints remains a critical workflow requirement for several reasons:

Liability and Validation: Contractors often cannot accept the designer’s model as the sole source of truth due to liability concerns. Independent validation of quantities is required to verify margins.

Complex Logistics: Calculating a wall dimension involves more than concrete quantities and steel reinforcement. GCs must assess constructability: casting methodology, casing module availability (standard vs. custom fabrication), and on-site laydown space.

The Tender Phase: During bidding, fully matured models are rarely available. Estimators typically work with initial PDF sets and tight deadlines.

Legacy and Handover Friction: Many projects involve existing structures with no existing models, or partial models that do not cover the full scope of work.

Kamai is an AI-powered engine designed to transform raw 2D blueprints—whether vector PDFs or raster scans—into verifiable, structured data without requiring a full BIM implementation. Utilizing computer vision rather than simple OCR, the engine distinguishes between architectural elements (walls, windows) and MEP symbols, recognizing that specific line combinations constitute defined "Rooms" or "Zones."

The core workflow automates the transition from raw upload to detailed estimation.

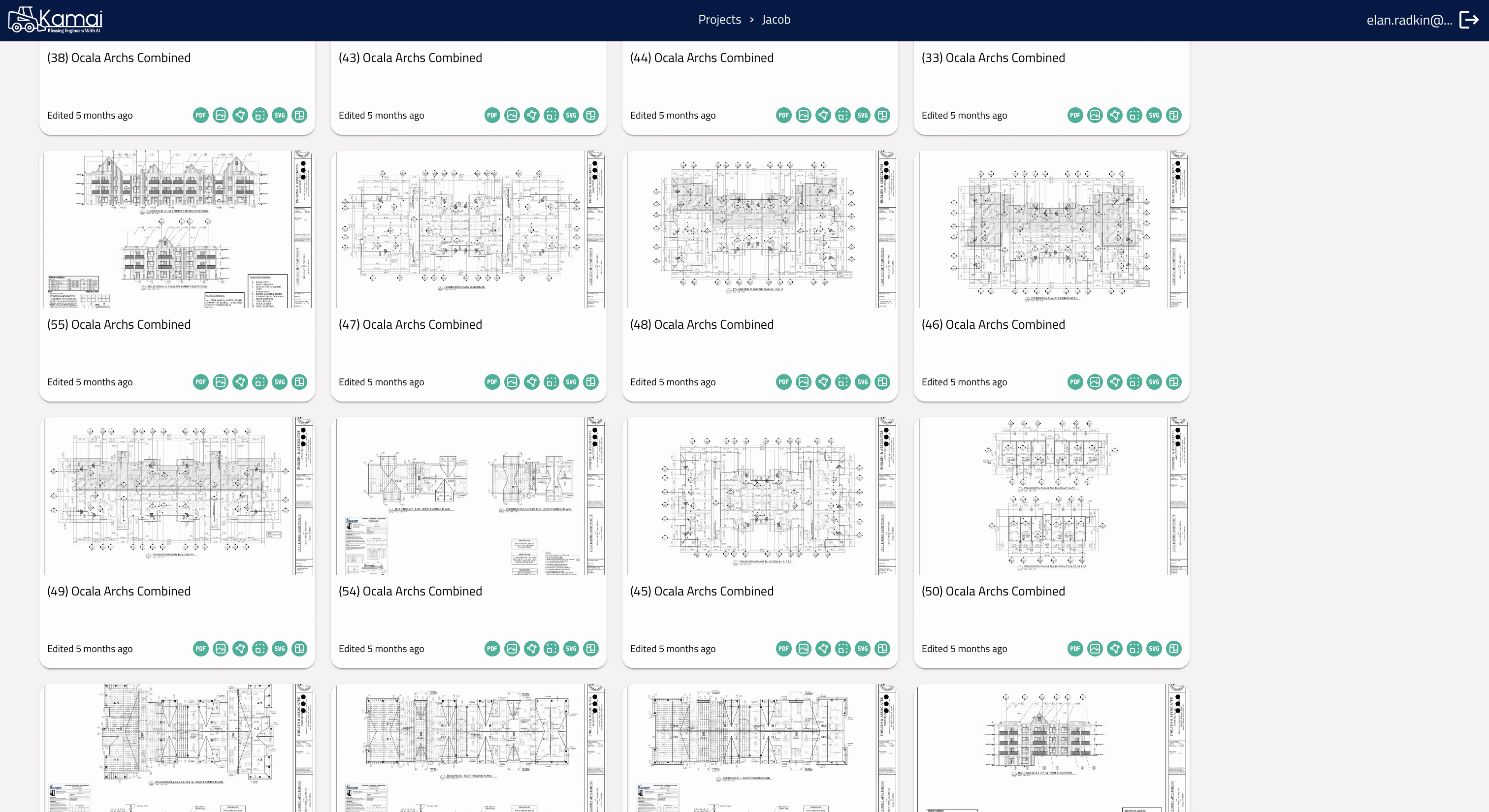

Input: The user uploads the full plan set, labeling the relevant discipline and floor hierarchy (e.g., Architecture Floor Plans B1-B4).

Processing: Upon upload, the engine immediately initiates pattern recognition across the document set to identify geometry and symbols.

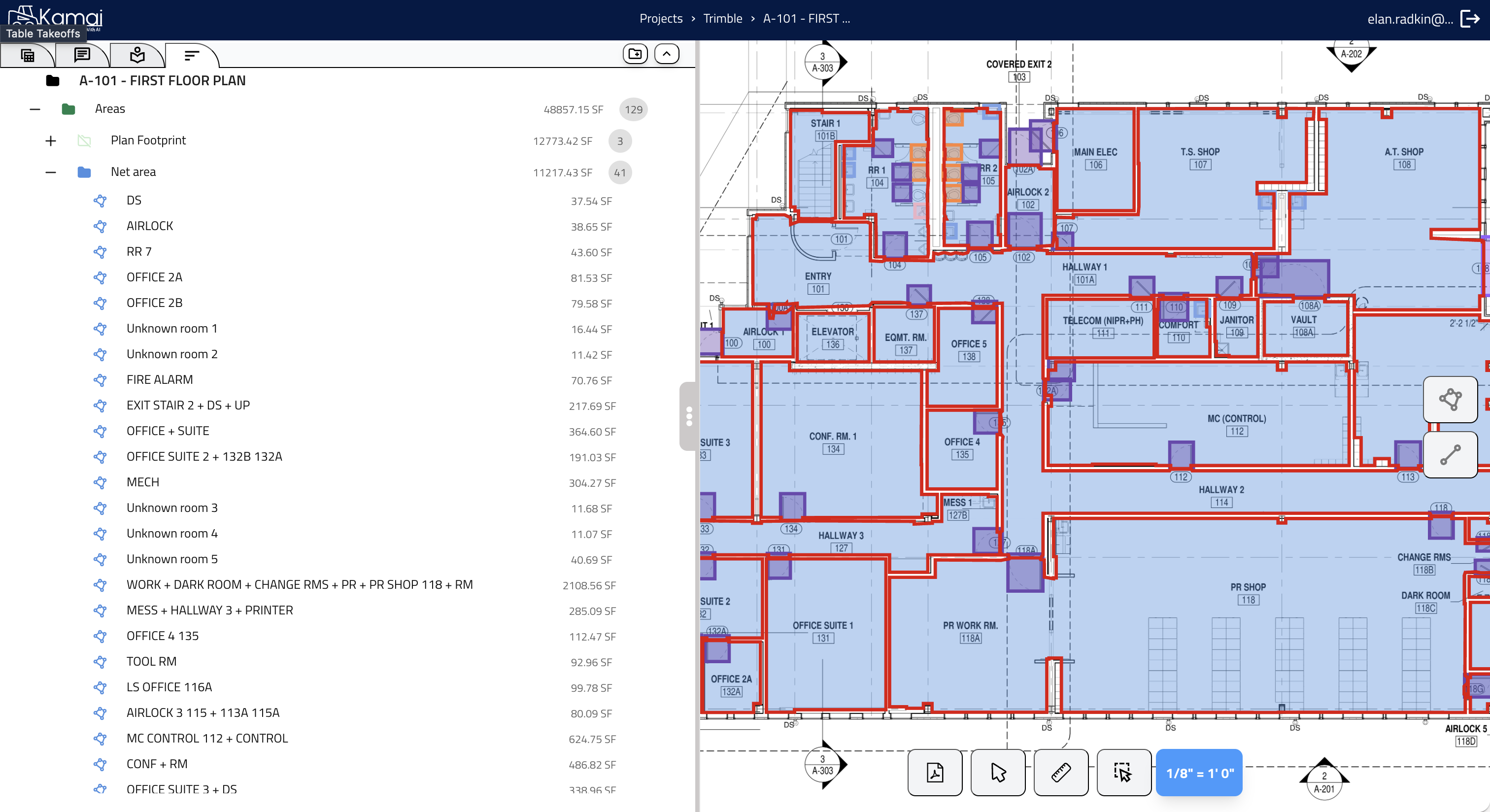

Extraction: With a single command, the system generates the quantitative data:

Architectural: Extraction of flooring areas, wall surface areas (paint/finish), and perimeter lengths.

MEP: Automated counting of fixtures/outlets and linear length extraction for piping or ductwork paths.

Structured Data Export: The system compiles the extracted geometry into standardized takeoff tables. It automatically maps identified zones to specific categories (e.g., Wet Rooms, Service Areas, Corridors), ensuring the output is delivered as a clean, structured dataset ready for external use.

The system is architected to handle full drawing sets rather than isolated sheets. When multiple files are uploaded, the engine identifies patterns and context across the entire set. This allows for project-wide summarization and tracking, replacing the need for manual sheet-by-sheet addition and ensuring continuity across different floor plans and disciplines.

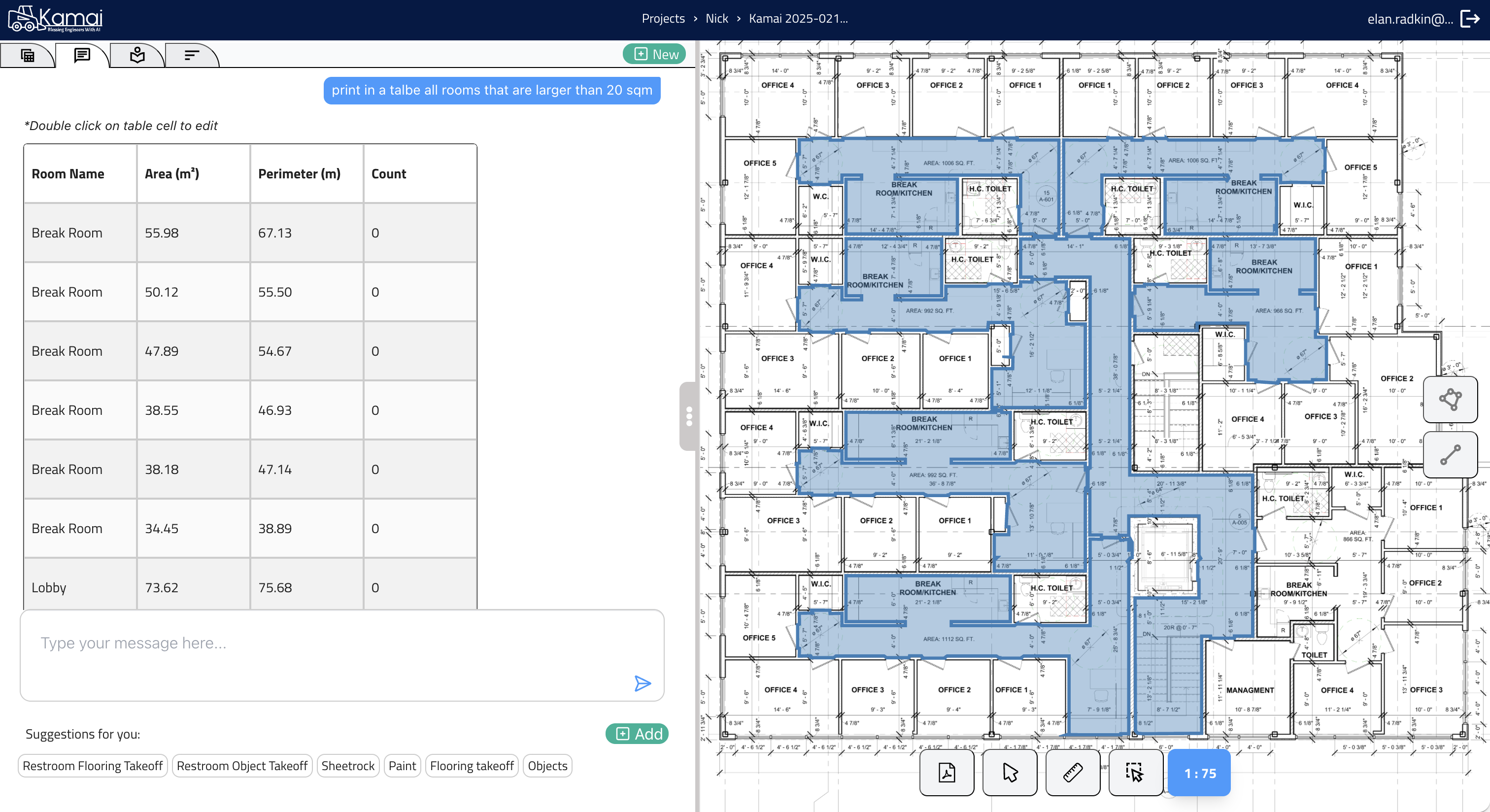

Beyond static data tables, the platform allows for interactive data querying. An Intelligent Chat Interface enables users to interrogate the uploaded files using natural language to retrieve specific data points without manual searching.

Instead of scanning columns in a spreadsheet, a user can query:

"Show me all rooms on Level 3 that are larger than 20 m²."

"What is the total linear length of interior walls on this floor?"

"Summarize the MEP fixture counts across all drawings in this set."

This transforms the blueprint from a document to be read into a dataset to be queried, significantly reducing the time required to answer RFIs (Requests for Information) or validate specific scope items.

The construction industry is moving toward data-driven decision-making, but this requires upgrading 2D workflows rather than abandoning them. By automating the extraction of quantities and enabling intelligent interrogation of plans, Kamai mitigates the risk of manual error and bridges the gap between static blueprints and dynamic project data.

No comments yet. Be the first to share your thoughts!